Vertical Farming

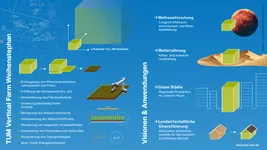

Vertical farming is an opportunity to produce large quantities of food with consistent quality, at any time of the year, on small areas and close to consumers. In vertical farms, all growth factors such as light (intensity, duration and spectrum), temperature, humidity, CO2 levels, ventilation, water and nutrients can be controlled and optimized. At the same time, weeds, pests and diseases can be excluded, eliminating the need to use pesticides and herbicides. Water and fertilizer use can be drastically reduced, with 90% of water reused and 60% less fertilizer needed per yield. This allows vertical farms to consistently produce high quality, fresh and healthy food close to the consumer, with minimal waste as part of a future circular economy.

Vertical farms currently consume a lot of energy. There is also a high need for research in plant growth optimization, computerized control and technical implementation, including automation. There are close links to nutrition and food sciences at the Weihenstephan campus, e.g. on questions of quality (taste, ingredients, etc.) of the food produced.

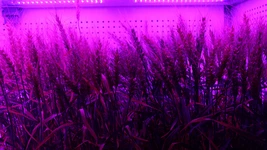

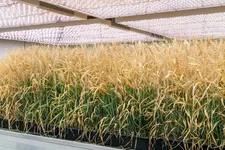

Experiments with wheat and soybeans are carried out in the vertical farming chambers at the Dürnast station on the TUM-Weihenstephan campus.

On the initiative of the Hans Eisenmann Forum (HEF) at the Technical University of Munich, the “Controlled Environment Agriculture” platform of the German Agricultural Research Alliance (DAFA) was launched in 2021. It aims to facilitate the exchange of research results through stronger networking. This promotes the identification of synergies, open questions and future topics and supports joint applications.

Further information on the website of the platform.

The world's population is expected to grow to over 9.2 billion people by 2050. This growing population will need to be supplied with food as urbanization progresses and agricultural land becomes scarcer. The Proteins4Singapore research program at the Singapore site of the Technical University of Munich draws on the expertise of renowned university and research institutions in the fields of materials science, process engineering and food chemistry to develop new proteins that are nutritious and tasty.

The project combines alternative protein sources such as microalgae, protein-rich plants or side streams from aquaculture with indoor farming concepts that are independent of arable land and climate change. These new protein sources are to be integrated into innovative processing methods. One of these is the use of innovative reverse food engineering. This technique breaks down and separates food into individual components to create foods with pleasing textures and enhanced sensory impressions - a crucial step in creating nutritious and high-quality foods

Drawing on expertise from various materials science disciplines, process engineering and food chemistry, the research will focus on establishing links between protein functionality, protein interactions with other ingredients, sensory properties and inherent processing methods using basic and applied analytical techniques.

Further information:

As part of the SpaceVOCs project, the researchers are developing an innovative olfactory monitoring system for the early detection of plant stress. The project aims to investigate the extent to which stress-specific odour patterns of plants can be detected and predicted using artificial intelligence methods. VOC sensor technology, which detects certain gases and smells (Volatile Organic Compounds/VOC) and their concentration, is being tested for the detection of plant stress. A large part of the task is to determine reference data that describes the “healthy” state, for example, or the state of certain disease patterns or stress situations at an early stage. This reference data is then used to identify and report deviations at an early stage so that countermeasures can be taken in good time. The aim is to minimize crop losses. The focus is on the crop plant wheat.