90 people on site and 200 online participants followed how experts from research, companies, start-ups and practice provided information on the current status of vertical farming and discussed its potential on the market. Claudia Luksch, Managing Director of the HEF, is convinced of the prospects: "By cultivating plants on the floors of a high-rise building, a hall or even just a container, the available space and the available resources are used as efficiently as possible. At the same time, vertical farming enables production that is decoupled from external influences and can make a decisive contribution to environmentally and climate-friendly food production at the point of consumption in the future. However, there is still a lot to be done: the task of university research is to close the existing gaps in knowledge of vertical farming until it is ready for the market".

Opportunities and possibilities of the indoor cultivation system

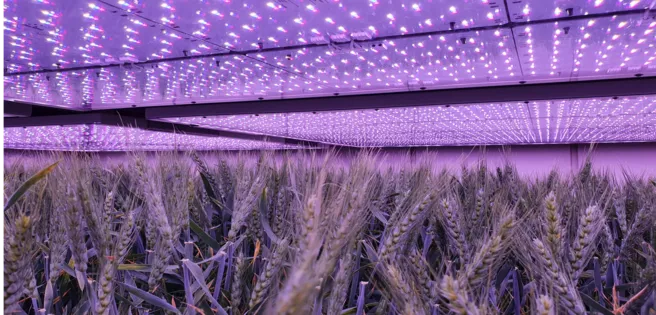

Prof. Senthold Asseng, director of the HEF with a research focus on vertical farming, described the possibilities of the indoor cultivation system. It ranges from cultivation in a small box to industrial workshops with several thousand square meters of space, which saves agricultural land. A high degree of mechanization, for example through fully automatic transport of the plants within the rooms as well as lighting and irrigation systems, reduces the operator effort to a minimum. In the closed system, which is shielded from the outside world, water consumption could be reduced by up to 90 percent and chemical plant protection could ideally be dispensed with altogether. The yield can be increased many times over by optimal supply and growth conditions.

However, vertical farming still requires a lot of energy, which initially makes it unprofitable for classic grain cultivation, for example. The effects on the quality of the grain is currently still open. Prof. Asseng still sees a great need for research, especially on the question of what actually limits plant growth in vertical farming. The use of energy and its utilization is also an important field of research.

Even if the new cultivation method will not completely replace classic arable farming, Asseng sees it as a significant part of food production in the future. In practice, the indoor cultivation method certainly offers opportunities. “We need farmers who want to use vertical farming for themselves. They have the important know-how in practical cultivation and bring a lot of plant system experience with them. Therefore, they should be included in the further development of vertical farming technologies,” appeals the scientist.

IT solutions for indoor farming

Nicole Thorpe, owner of Cultinova, a German-British company for IT solutions in indoor farming systems, emphasized that food should be sustainably produced, safe, fair and healthy. This is the only way to actually achieve the goal of climate neutrality. The technology still has great development potential. At the same time, she called for further efforts to increase efficiency in order to make vertical farming economical. "Vertical farming only makes sense if we earn money with it, i.e. if it is also economically sustainable". She sees the expansion of product variety as an important success factor. The expert predicts good prospects, especially for protein plants and plants used in the pharmaceutical industry.

Bavarian salad in tiered greenhouses

Jochen Haubner, master gardener in vegetable cultivation from the garlic region of Nuremberg is already using vertical farming in a part of his business. "Vertical farming is trendy, but in practice it has to be profitable for the business after one or two years," says the vegetable farmer. His motto is cultivation that is as cost- and resource-saving as possible. The system must be durable and efficient in practice. The practitioner demands: "In spite of all theory and research, the way of thinking of the gardener must be incorporated!" He sees the necessity of using plant protection measures in vertical farming: "Something will always develop: regardless of whether it is diseases or pests. This raises the question: What is necessary, what is permitted, are there auxiliary substances or even microorganisms that can be used to counteract the infestation?” says Haubner.

By interlinking science and practice to success

A top-class panel discussion with experts from research, companies and professional associations illustrated the prerequisites for the successful establishment of vertical farming on the market. Prof. Heike Mempel from the Weihenstephan-Triesdorf University of Applied Sciences called for a large-scale demonstration project that should be open to the networking of research and industry. Andreas Schmitt from the Bavarian State Institute for Viticulture and Horticulture (LWG) explained that practice-oriented research could be a key driving force for vegetable growing companies that are economically oriented. Vertical farming is currently too far away from practitioners. Lisa Puschak from the Bavarian Farmers' Association also emphasized that the success of a cultivation system lies in its profitability for the farms. Vertical farming will only succeed in practice through strong cooperation between research and the will to innovate in agriculture. Alexander Gerfer from Würth Elektronic eiSos emphasized that vertical farming must be applicable in practice, whereby science must close the gaps that still exist in the implementation.

Success stories from the industry - vertical farming on a large scale

Vertical farming has already arrived in the industry. Two international companies reported on their experiences. Infarm – Indoor farming GmbH presents its indoor farm as a transparent greenhouse in the German retail trade. Customers can watch live how the products grow and can buy them freshly harvested. dr Pádraic Flood, Team Lead Crop Genetics, highlighted breeding advances as a key success factor. Plants that provide protein and carbohydrates are particularly important for supplying the world's population. Here it is important to find new plant diversity for vertical farming. In the search, infarm also resorts to traditional, almost forgotten crops, such as the tuber vetchling, which provides both protein and carbohydrates, but can also be used as a salad.

Daniel Lock, Vice President Business Development, presented the company Kalera GmbH, which took over the Munich start-up &ever at the end of 2021 and is one of the world's leading companies in the field of vertical farming. Kalera specializes in the production of leafy greens such as spinach, rocket, watercress and coriander. Half a tonne to four tons of harvested material is produced per system every day. Fully automated production halls up to 20 meters high are located in Kuwait and in the future also in Singapore.

Vertical farming competition – “Berry” wins

At the event, five start-ups presented their ideas in the field of vertical farming and competed against each other in a pitch. They showed the enormous range of applications of vertical farming: From the use of robots for fruit harvesting (www.organifarms.de), to fully automatic plant systems (www.roko-farming.de), modular plants using expandable container construction (www.mabewo.com) to one vertical parking tower, the facade of which is to be greened (www.vepa.space). The Expert Choice Award was presented by the speakers at the event, as well as the Public Choice Award, the winner of which was chosen by all participants. The Konstanz start-up Organifarms convinced both the jury and the participants and won both prizes. The company from the robotics research field was founded in 2019 and offers the harvesting robot "Berry" for strawberry harvesting as well as the user interface and the corresponding cloud solution. Founder Hannah Brown accepted both awards.